Company news

ClassifyCompany news

How do you recycle plastic and crush it?

Source:本站 Time:2025/1/16 15:21:47 frequency:

Plastic Recycling from the Plastic granulator industry This is an industry that collects plastic scrap or plastic waste through the crushing process. Become a ready material for plastic pelletizing plants (plastic pelletizing plants) and factories that produce finished plastic products, each plastic has a different value. And will not be combined and crushed but each type will be crushed separately. It depends on the competence and expertise of the entrepreneur.

Plastic digestion steps and processes

Plastic crushing is a simple process that requires only the expertise to classify the type of plastic to be broken and the precision of each step, as it is a continuous process. Every plant has the same crushing process. After the grinding process. The resulting plastic fragments will become semi-finished raw materials for plastic pelletizing plants.

The recycled plastic crushing process has the following steps:

Step 1: Collect plastic

Plastic shredding starts with collecting old plastic. Much of it is collected in industrial waste recycling and consumer waste and then piled up for further sorting.

Step 2: Classify the recycled plastics

The plastic obtained when the factory acquires old plastic will be sorted according to the type and color of the plastic. And separate the cap from the bottle This is because most plastic bottles and plastic caps are different types of plastic. This step requires a lot of touch sorting knowledge and expertise. But if some plastic cannot be separated by touch, it will be burned to prove the smell, because each plastic has a different unique smell.

Step 3: Clean the plastic

Once the plastics are sorted by type and color, the plastics are cleaned. By cleaning the plastic this is not washing the plastic bottle clean. But it's about removing the advertising signs, labels and straws attached to the plastic that will be shredded. If the plastic to be shredded is large, it will be cut into smaller sizes and then fed into the plastic shredder.

Step 4: Plastic crushing

The cleaned plastic is sent to the plastic granulator according to the type and color of the plastic. The dimensional operator of the broken plastic can select or scale the desired resolution.

Step 5 Clean

Cleaning it can clean all kinds of dirt particles. Something attached to a plastic bottle.

Step 6 Dry

Drying involves shredding pieces of plastic that have been cleaned and dried to prevent mold from forming on these pieces.

Step 7 Packaging

The crushed plastic will be packed into the bags that have been prepared. The ropes are then neatly collected, prepared, transported and sold to customers.

Production process of recycled plastic particles

Plastic recycling process This is the process of converting plastic waste into a form that can be used in other areas. The steps through the plastic recycling process first place the crushed plastic waste into the plastic melting/rolling machine. The plastic is a material with special properties unlike glass and metal, they can be easily recycled. Each type of plastic has specific properties. For example, the arrangement of polar hydrophobic grade molecular structures, etc., makes it impossible for each type of plastic to be mixed into a single substance, and the plastic should be melted/rolled into different types.

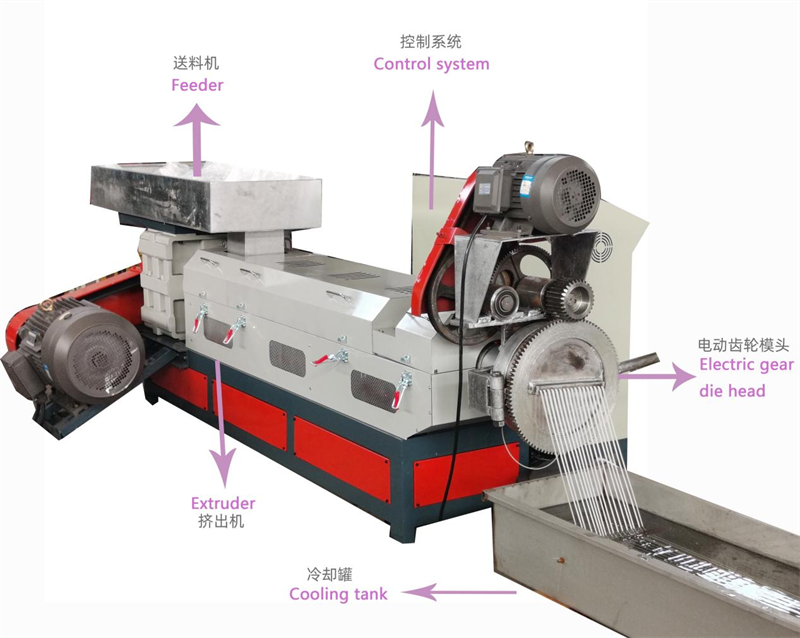

Melting/rolling plastic sheets It involves heating plastic sheets until they soften and become uniform, then using mechanical energy to feed them into an extruder. This squeezes the plastic into strips, which are then run through cold water to lower the temperature. The plastic will be cutting into the plastic particles that need to be recycled according to the following steps:

The first step is to mix the primary color with the obtained plastic waste. Make the obtained plastic particles have the same color. This primary color is available in two granular forms.